The Do-It-Yourself movement is now expanding beyond products to the materials that embody the products themselves. [1]

In comparison to the industrial ones, DIY-Materials are "created through individual or collective self-production practices, often by techniques and processes of the designer's invention. They can be entirely new materials, modified or further developed versions of existing materials". [2]

One of the most interesting parts of DIY practices is they ground on experiential knowledge, on knowing in action through the material at hand (Schön, 1983).

I had the opportunity to attend a lecture on DIY-Materials by Marta Gonzalez, Ph.D. in Science of Materials and Metallurgic Engineering, and Senior Researcher in Elisava Research, and I'll share an outline of it here, with examples of their applications.

To give a general view on the topic we will look at the different sources that compose DIY-Materials as a distinctive feature to classify them, as exposed by Ayala, C., Rognoli, V. et al. (2017) in Five Kingdoms of DIY-Materials for Design. [4]

Adaptation of taxonomy for DIY-Materials. Five Kingdoms of DIY-Materials for Design (2017).

This paper takes inspiration by the first biological classifications of the XVII century (e.g. the work of the Swedish botanist, zoologist, and physician Carolus Linnaeus called Sistema Naturae (Linnaeus, 1758), focusing on the sources of the material and their origins, and classifying DIY-Materials in five main categories: [5]

Vegetabile:

When the primary source for a DIY-Material derives from plants and fungi. Materials under this kingdom differ from the others, particularly because they can derive from growing or farming techniques.

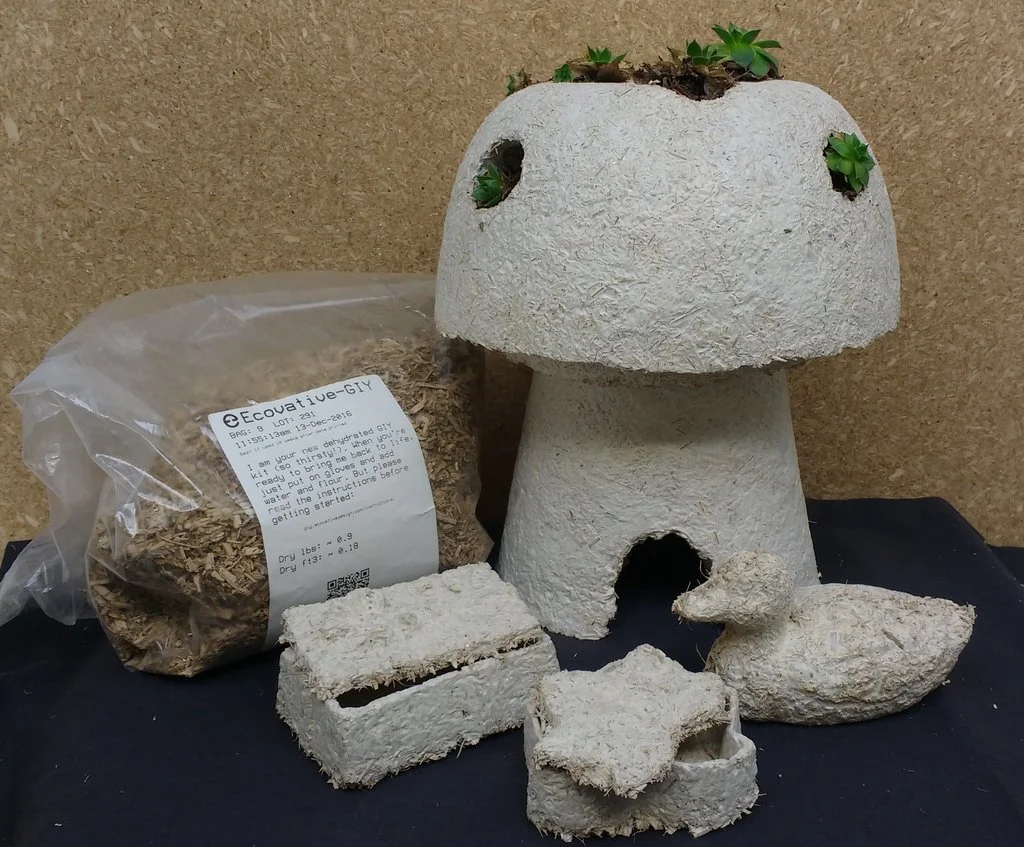

Ecovative for example, proposes an alternative to expanded polystyrene that goes beyond the concept of DIY, with the idea you can Grow It Yourself. Using mycelium (the root structure of a mushroom) purchased in a bag, mixed with flour and water, you can fabricate your own creations.

Agar Plasticity is an ongoing development by Japanese AMAM Studio led by designer Kosuke Araki. With the intention to replace different plastic-made products, they explore the potential usefulness of agar as a packaging material.

With different concentrations of agar and algae, various hardnesses and thicknesses can be attained. For example, this composite material can be used as wrapping for flowers, or as cushioned packaging for plant pots and wine bottles, or molded to make boxes.

Wrapping for flowers / cushioned sheet for plant pots - Kosuke Araki

Animale:

Refers to all material sources derived from animals and bacteria. Those materials can be developed either by collaborating with living organisms or by using parts of the animals like hair or bones.

Suzanne Lee of BioCouture proposes the use of microbes to make clothes. Certain bacteria will spin microfibrils of pure cellulose during fermentation which form a dense layer that can be harvested and dried to produce a textile biomaterial.

“Through an engagement with biology, I’m really excited about how we can think about organisms like microbes as the factories of the future.”

Lapideum:

It contains all DIY-Materials which come from minerals, stones, sand, ceramics, clay, etc. Another feature of this kingdom is its strong link to crafts.

Marwoolus is a material developed by Marco Guazzini where two opposite sources meet: marble and wool. The uncommon mix derives from the cultural connections of the designer with places where both materials are extracted and processed, achieving a beautiful, colorful material with expressive qualities.

Balloon Bowls is a project by Maarten De Ceulaer to explore outside of traditional industrial processes. By inserting a type of clay with a polymeric hardener in the middle of two air-inflated balloons the designer can create unique bowls, making each piece different in shape and visual texture.

Recuperavit:

Comprises all sources society considers as waste but have the possibility to transform into a valuable source. They often come from plastic, metal or organic waste, sometimes as side products of industrial production, with an intention towards a more sustainable future.

Decafé is a project by Raul Lauri with a concern derived from the excessive amount of food waste produced by humans. Decafé offers lamps and accessories made of coffee to create a biodegradable, sustainable product that enhances its materials properties.

Even human hair has been proved to be reusable. In the US alone, 60 million pounds of human hair are disposed of in landfills each year and it does not degrade well. OttiMat is an innovative product that uses recycled human hair to repair and prevent the environmental damage caused by oil spills. Human hair is easily available, low cost and avoids the use of toxic oil cleaners in our water sources.

I touched a sample of this one too. Definitely not my favorite material judging by it sensory qualities but it's clever and cost-effective.

Mutantis:

Includes the DIY-Materials created from different technological mixes and hybridization of industrial, interactive or smart sources. It includes all cases where transformation occurs with the aid of technology, to represent a significant change in the material's nature.

The Gravity Tool is a machine existing out of large magnets that are pulled upwards by two weights. By pulling up the magnets new shapes and structures emerge.

Through the Gravity Tool and the two-component plastics – developed especially for this purpose – Jolan Van der Wiel was able to produce a small collection of objects ranging from his Gravity Stools to custom orders and collaborations with other designers and architects.

Without a doubt, the democratization of technologies [6], and the growing practices of crafting and personal fabrication [7] give designers more tools for creation.

As much as we give value to the end product, it is worthwhile to study the elements with which we are fabricating what we do. Do you know where your materials come from and how they are made?

We are creators of the product but we can also create the fabrication process, and perhaps—like Marco Guazzini with his Marwoolus material—we can even imbue what we make with our personal journey and the resources available right next to us.

References

(1) Brownell, B. (2015) DIY Design Makers Are Taking On Materials. Retrieved July 22, 2018 from:

http://www.architectmagazine.com/technology/diy-design-makers-are-taking-on-materials_o

(2) Rognoli, V., Bianchini, M., et al. (2015) DIY Materials. Special Issue on Emerging Materials Experience, Materials and Design, Vol. 86, pp. 692-702.

(3) Schön, D. (1983) The Reflective Practitioner: How Professionals Think in Action. New York, NY: Basic Books.

(4) Ayala, C., Rognoli, V. et al. (2017) Five Kingdoms of DIY-Materials for Design. Conference Paper. Retrieved July 15, 2018 from: https://www.researchgate.net/publication/318787525_Five_Kingdoms_of_DIY-Materials_for_Design

(5) Linnaeus, C. (1758) Systema naturae per regna tria naturae: secundum classes, ordines, genera, species, cum characteribus, differentiis, synonymis, locis (in Latin). (10th ed.) Stockholm: Laurentius Salvius.

(6) Tanenbaum, J.G., Williams, A., et al. (2013) Democratizing technology: pleasure, utility and expressiveness in DIY and maker practice. In: Proceedings of SIGCHI Conference on Human Factor in Computing System, CHI 2013, pp.2603-2612, April 27-May 2, Paris, France.

(7) Gershenfeld, N. (2005) Fab: The Coming Revolution on Your Desktop - From Personal Computers to Personal Fabrication. Basic Books.